86-755-27501726

Date:2022-10-29 Edit: Read: 1898

Blanking:

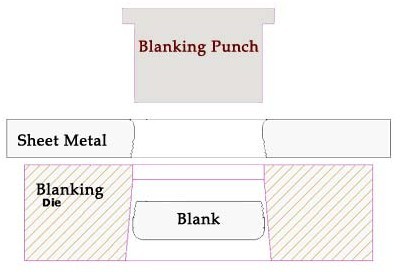

Blanking is a High precision metal stamping operation by which the sheet metal is punched to get the required outer profile of the sheet metal component. During the blanking processthe blanking punch penetrates into the sheet metal and forces the material into the blanking die. The portion of the sheet Metal which comes out through the blanking die opening is the component with the required profile. Hence it is important that the dimension of the blanking die profile is equal to the dimension of the component profile. In blanking tools the cutting clearance is given on the blanking punch.

Types of Blanking Dies

Blanking dies can be a single stage press tool where the component is produced in each stroke of the blanking press. In single stage blanking tools there could be many stamping operations done prior to the blanking or those operations could be done after blanking depending upon the complexity of the blanking profile of the part, sheet thickness, dimensional importance of different stamping operations required to produce the final component etc.In progressive blanking press tools, stamping operations like piercing, bending and forming are done in various stages prior to the blanking stage. In the blanking stage the final component is punched through the blanking die.

Blanking Die Design

See the below drawing for a simple blanking die design. The portion of the sheet metal which is punched through the die is the blank or the component.

Note that the blanking die is provided with an angular relief after a certain length of straight land. This is to ensure that blanks which are punched through the blanking do not get stacked up inside the die. Otherwise the blanks get accumulated through thickness of the blanking die and can cause damage to the blanking tool. As a general rule the straight land is 3 mm for sheet thickness lesser than 3mm and for sheet metals above 3mm thickness, the straight land can be equal to one sheet thickness. The amount of angular relief is normally from 0° 30' to 1° per side.

Bending tools are used for bending the sheet metal to the desired shape and angle. Bending can be performed on sheet metals using bending tools, and bending machines. Normally bending tools and press brakes are used for precision sheet metal bending. For pipe bending and wire bending, suitable bending machines can be used depending upon the size and severity of the bending.Precision sheet metal bending can be a single stage operation where a single stage or it could be a series of bending done on a progressive bending tool or on a press break to achieve the required profile.

Bending tools are used for bending the sheet metal to the desired shape and angle. Bending can be performed on sheet metals using bending tools, and bending machines. Normally bending tools and press brakes are used for precision sheet metal bending. For pipe bending and wire bending, suitable bending machines can be used depending upon the size and severity of the bending.Precision sheet metal bending can be a single stage operation where a single stage or it could be a series of bending done on a progressive bending tool or on a press break to achieve the required profile.